In the current world of electronics, printed circuit boards (PCBs) are one of the most crucial components that serve as a building block for almost all electronic products. Everything from mobile phones to medical devices, and from industrial equipment to home automation devices, PCBs are busy providing operational connection. Due to the growing demand for small and efficient technology, printed circuit board manufacturers in India have witnessed their roles grow tremendously. India has become the destination of choice for PCB manufacturing with high-quality solutions being developed for design and fabrication, and materials for local needs.

Key Processes Involved in the Production of Printed Circuit Boards

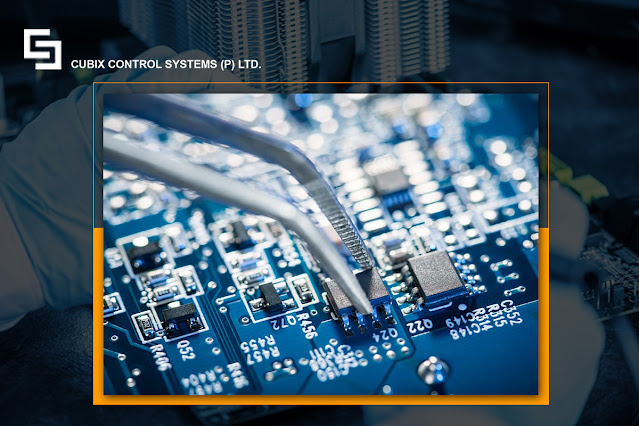

Manufacturing of PCBs is a meticulous process involving several cautious steps, each crucial to the final product's reliability and quality. It begins with the application of computer-aided design (CAD) in designing the circuit layout, which allows engineers to trace pathways as well as locate components. Once the design is done, the layout is transferred to the board using photolithography or digital printing techniques. This is followed by etching, whereby excess copper is removed to leave the conductive traces exposed. Drilling comes next.

It is done to create holes for lead components, and thereafter plating, solder masking, and silkscreen printing to complete the board. Last but not least, rigorous quality testing ensures that all PCBs meet the desired electrical as well as mechanical standards.

Applications of Board Printed Circuits in Various Fields

Printed circuit boards find applications in almost every sector of the economy. You will find these elements include daily products such as mobile phones, laptops, and home appliances. They are also found in cars for dashboard electronics and driver-assist systems. They are also key elements in the medical field of machines, pacemakers, and medical diagnostics. In industrial automation, they are key in device-controlling units and robotics, as well as for monitoring devices.

Everything from design to production, quality control to sustainability, everything depends on the experienced and skilled labor of an electronics manufacturing company. They are not simply making circuit boards, they are building the electronics future, with precision, imagination, and an appreciation for perfection.