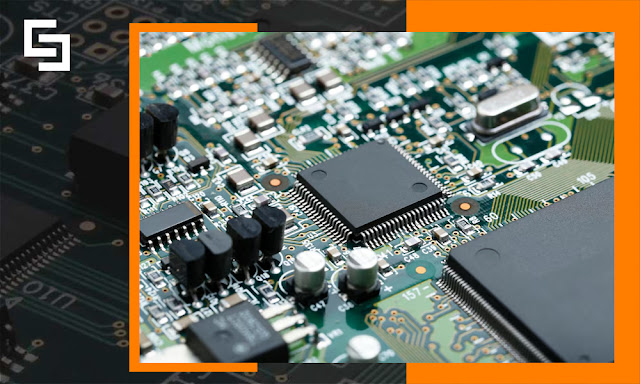

Are you looking for a Printed Circuit Board Assembly service provider? If so, look no further than Cubix Control Systems. It is one of the leading Printed Circuit Board Manufacturers and PCB Assembly.

Cubix Control

Systems creates precision-made PCB assemblies for medical equipment that

require very high quality and reliability. One important and essential thing to

keep in mind is that the PCB design plays in the performance of the assembly. The

design layout focuses on component placement, routing, signal integrity, and

others. Moreover, the types of materials and manufacturing techniques can impact

the board's electrical features and thermal management capabilities.

Besides, it

holds ISO 9000 (9001:2015) certification which is a source of pride for them.

It indicates that they provide measurable high-quality electronic contract

manufacturing services that meet or exceed customer expectations.

Why Choose Cubix Control Systems?

With abundant

experience in printed circuit board assembly, Cubix Control Systems has a

dedicated quick-turn PCB assembly line. These circuit boards are responsible

for the operation of equipment, data processing, and communication with other

systems.

Furthermore, it

deals with cutting-edge software to monitor and control every printed circuit

board assembly manufacturing process.

New Product

Introduction is a challenging phase in a product’s life cycle. Cubix Control

Systems provides the breadth of services and experience to smoothly transition

your new product from concept and design through to volume production.

The latest PCBA

(Printed Circuit Board Assembly)

design by Cubix Control Systems is ready to revolutionize your electronics

projects. With cutting-edge technology and meticulous craftsmanship, they

ensure top-notch quality for every PCB assembly.

Being a Printed

Circuit Board manufacturer, their main focus is custom Printed Circuit Board

Assembly (PCBA). They are dedicated to retaining their position as one of the

highest-quality PCB manufacturers and assemblers in the market.

They are

involved in these industries: New energy, Automated, Smart Home, Communication,

Microwave radar modules, Industrial, Agriculture, Medical Area, Security, and

more.

Following Services are provided:

·

Production

of printed circuit boards

·

Cloning

of printed circuit boards

·

PCB

assembly

Let's power up your innovations together! Enjoy competitive prices without compromising on quality.

.jpg)